- About Us

-

Services

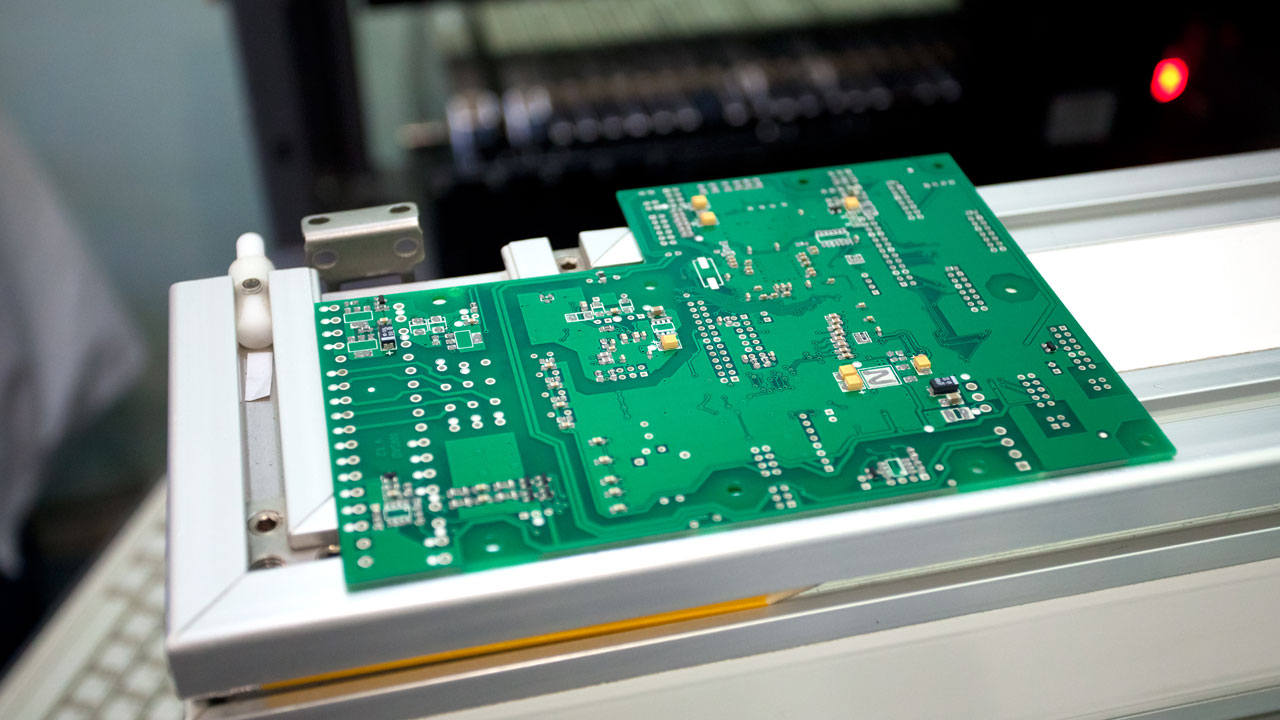

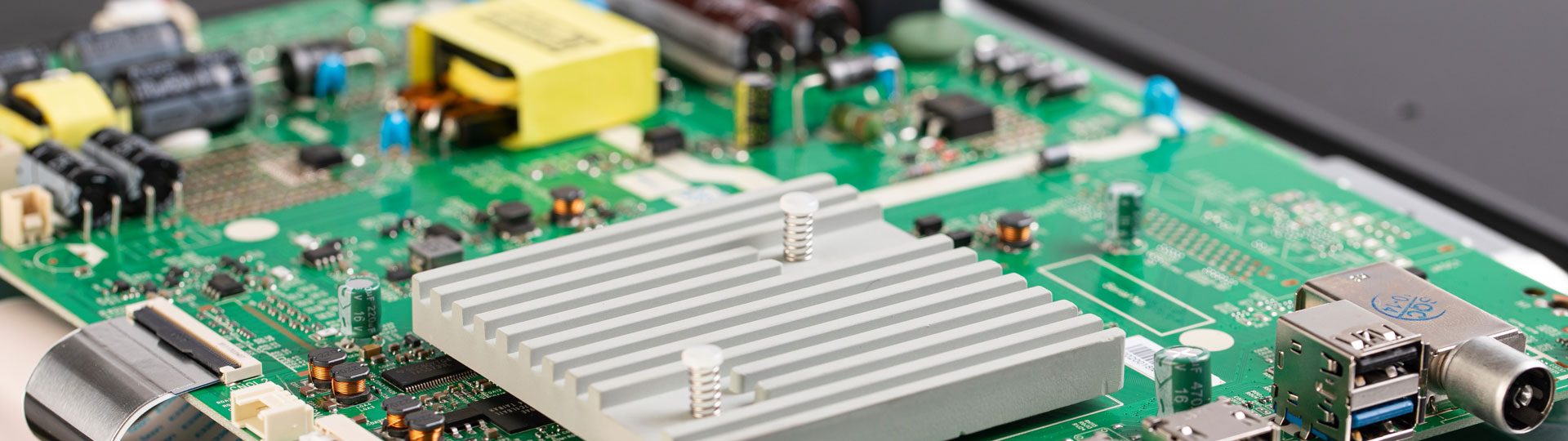

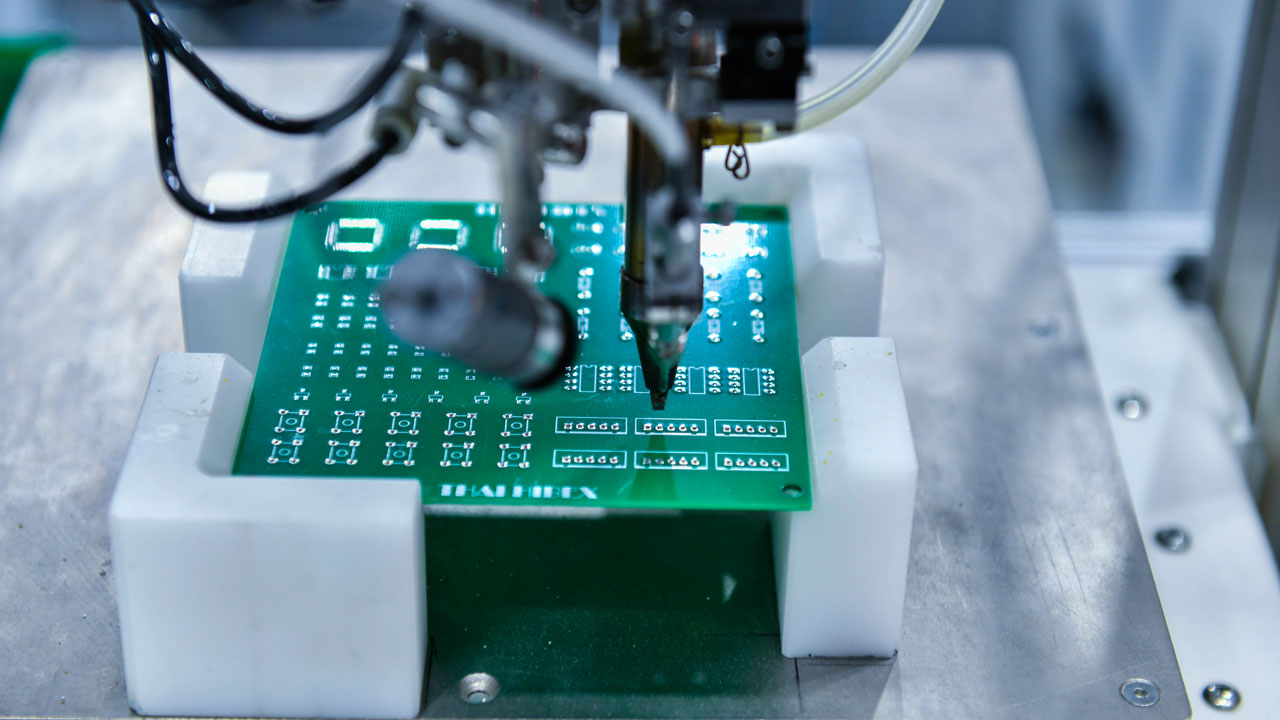

Our Services

Your one source for prototype builds, production runs, and turnkey PCB assembly solutions delivered with speed and reliability.

- Facility

- Industries

- Downloads

- Careers

- What's New?